A

archive10

Guest

I'm reviving this old Triax polar mount.

The mount swivels on a set of plastic bushings.

(Nylon, probably. Reminds me of roller-skate wheels.)

I'm trying to figure out two things:

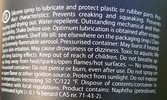

a) how to treat the ageing plastic parts so they become weather resistant

b) how to lubricate the mechanism properly going forward

So the first question is:

What to do to the plastic bushing to make them last another 10 years?

Soak them in oil?

Cover in Vaseline?

Automotive lubricant?

As for what to lubricate, I can't figure out the swivelling mechanism.

What parts move, and what parts don't?

The axis is a threaded bolt.

On the axis there's a washer, and then a big-diameter rusty washer.

Then there's a metal tube, which seems to have a thread inside it (so it doesn't move).

Around the metal tube, the two halves of plastic bushings are fitted.

The metal flap of the swivelling bracket fit in between the plastic bushings.

My current gues is that the evertying including the plastic bearing are kept stationary, and the metal flap of the moving bracket glides within the plastic bearings.

Any thoughts on what to lubricate, and with what?

The mount swivels on a set of plastic bushings.

(Nylon, probably. Reminds me of roller-skate wheels.)

I'm trying to figure out two things:

a) how to treat the ageing plastic parts so they become weather resistant

b) how to lubricate the mechanism properly going forward

So the first question is:

What to do to the plastic bushing to make them last another 10 years?

Soak them in oil?

Cover in Vaseline?

Automotive lubricant?

As for what to lubricate, I can't figure out the swivelling mechanism.

What parts move, and what parts don't?

The axis is a threaded bolt.

On the axis there's a washer, and then a big-diameter rusty washer.

Then there's a metal tube, which seems to have a thread inside it (so it doesn't move).

Around the metal tube, the two halves of plastic bushings are fitted.

The metal flap of the swivelling bracket fit in between the plastic bushings.

My current gues is that the evertying including the plastic bearing are kept stationary, and the metal flap of the moving bracket glides within the plastic bearings.

Any thoughts on what to lubricate, and with what?